Location: Memphis, Tennessee

Industry: Higher Education

Products Used: Chillers, Controls, Building Automation Systems

Topic: Efficiency, IEQ, Financial Solutions, Building Automation Upgrades

- 10 added years of chiller lifetime expectancy

- 80-85% capital investment reduction

- 48 weeks replacement downtime avoided

Highlights

- Extended chiller life expectancy by nearly a decade, delaying the need for full replacements and reducing capital costs by 80—85%

- Staggered refurbishments helped provide continuous cooling, with only three weeks of downtime per unit

- Elevated system stability and climate control for research labs and other campus spaces

Challenge

The University of Memphis is committed to conducting cutting—edge research. Maintaining precise temperature and humidity control across its campus, particularly in research labs, is critical to ensuring the integrity of experiments and other activities.

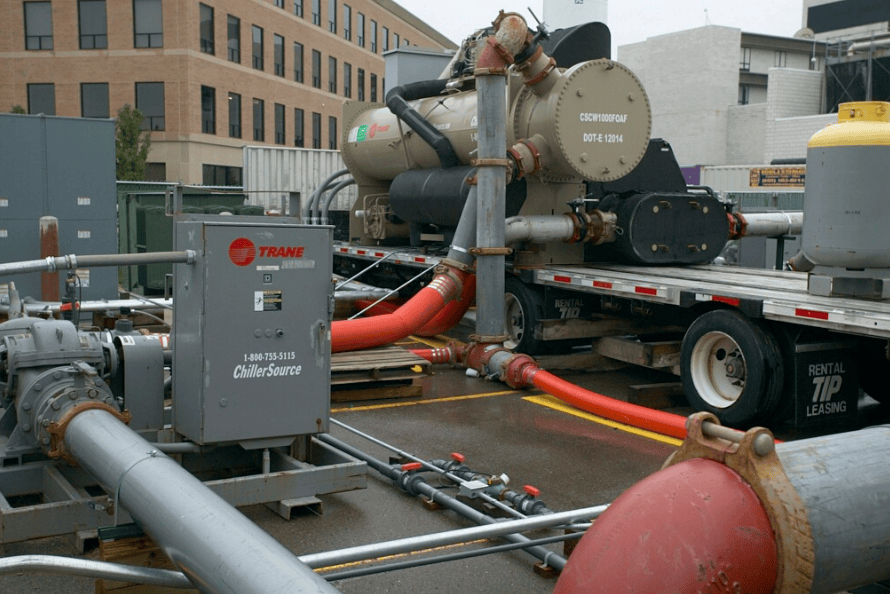

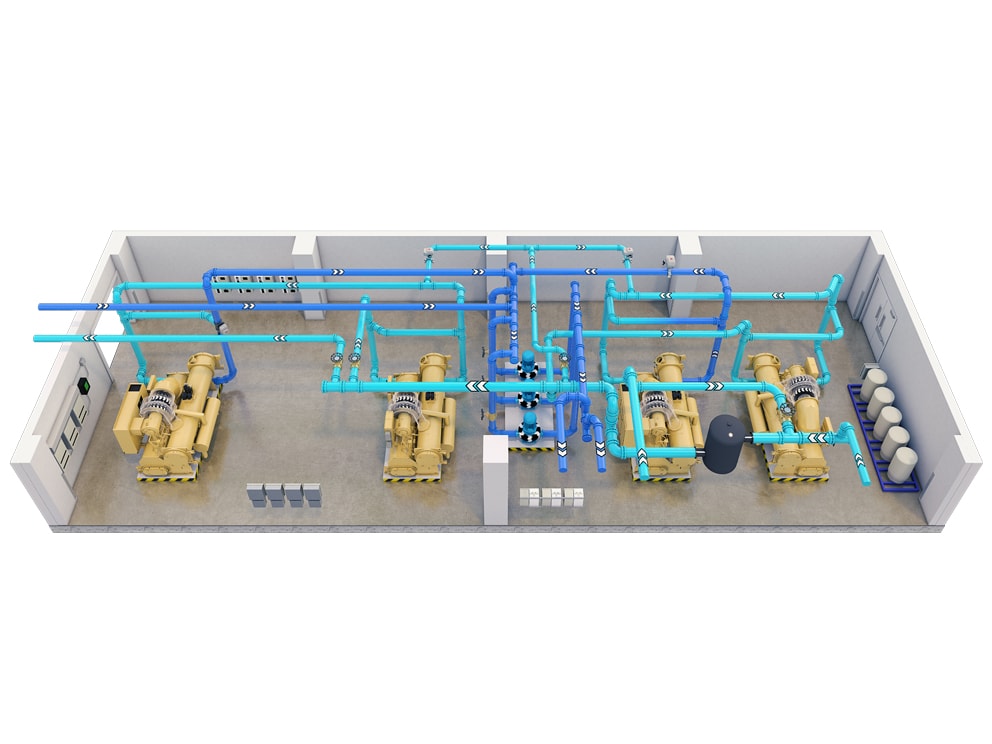

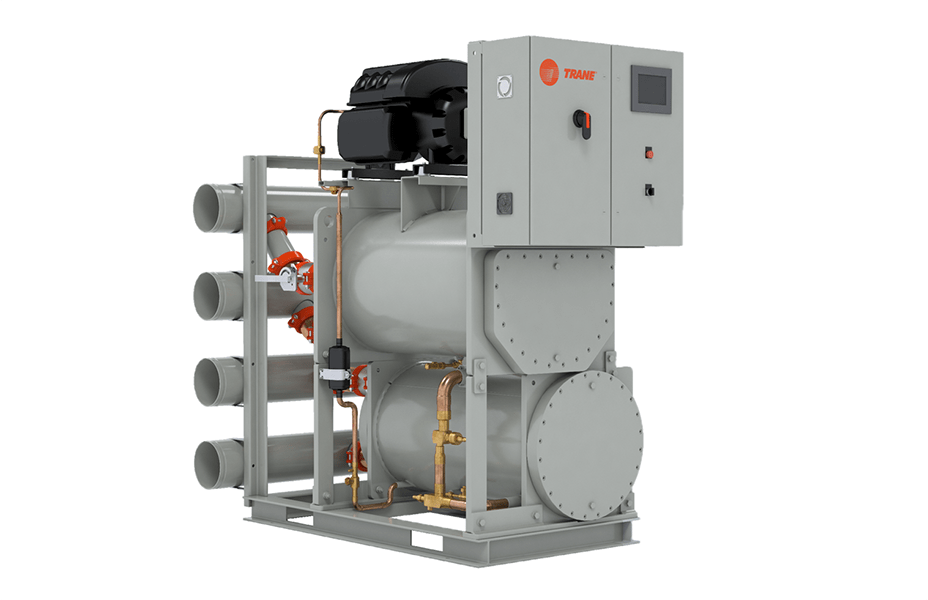

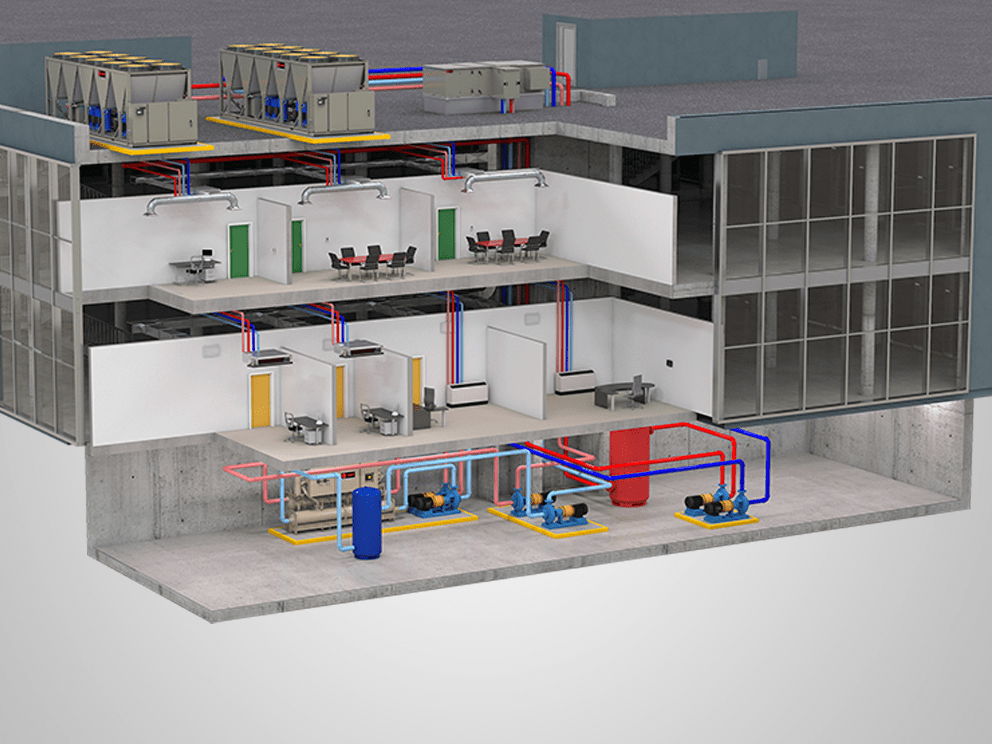

However, the university faced a significant infrastructure challenge. Four 1,280—ton centrifugal chillers, responsible for cooling multiple buildings on campus, were nearing the end of their operational lifespan. Replacing these chillers carried an estimated cost of $5 million, a budget the university simply did not have. Additionally, the lead time for new chillers was upwards of 48 weeks, meaning an extended period without proper climate control, which was an unacceptable risk for a campus with high-priority research facilities.

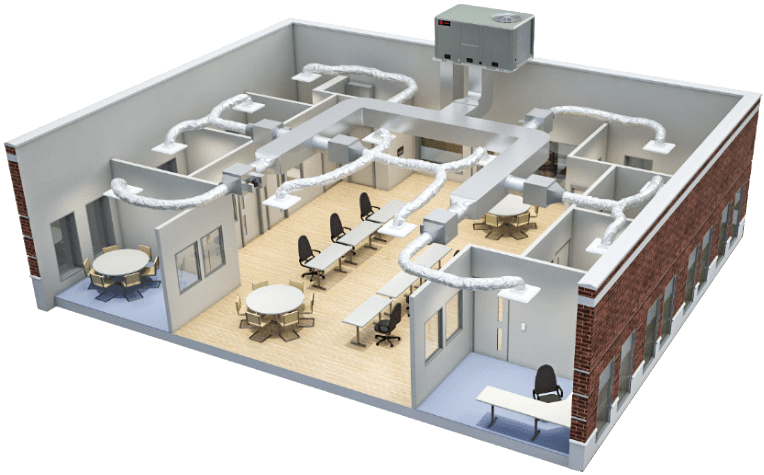

Beyond financial constraints, the university’s outdated building automation system limited efficiency and system optimization. Without a comprehensive solution, the institution risked increased energy consumption, ongoing maintenance costs, and potential disruption to critical academic and research functions.

Solution

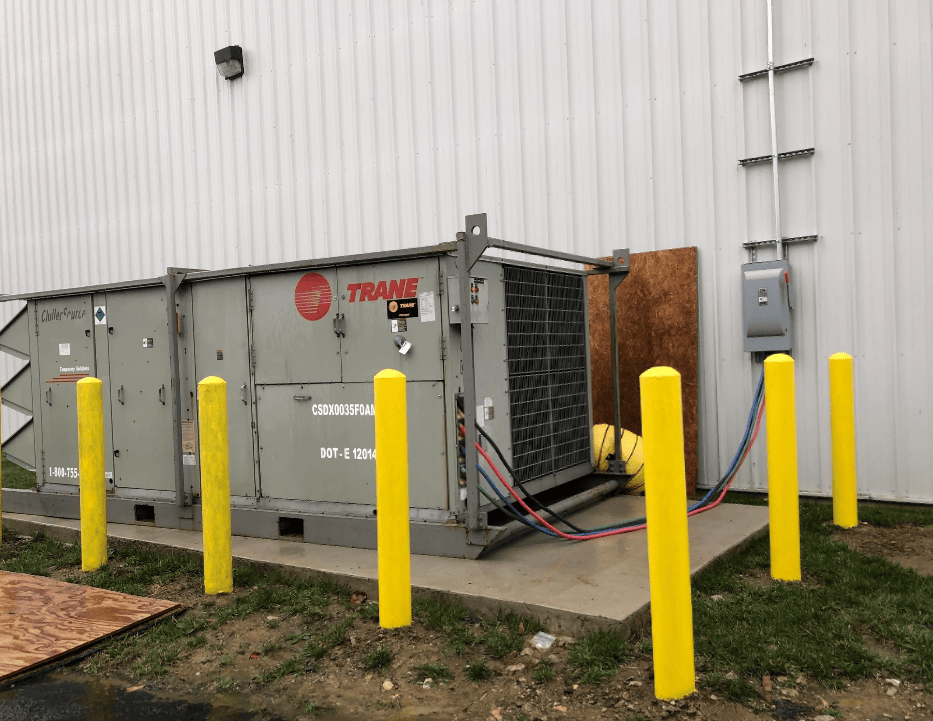

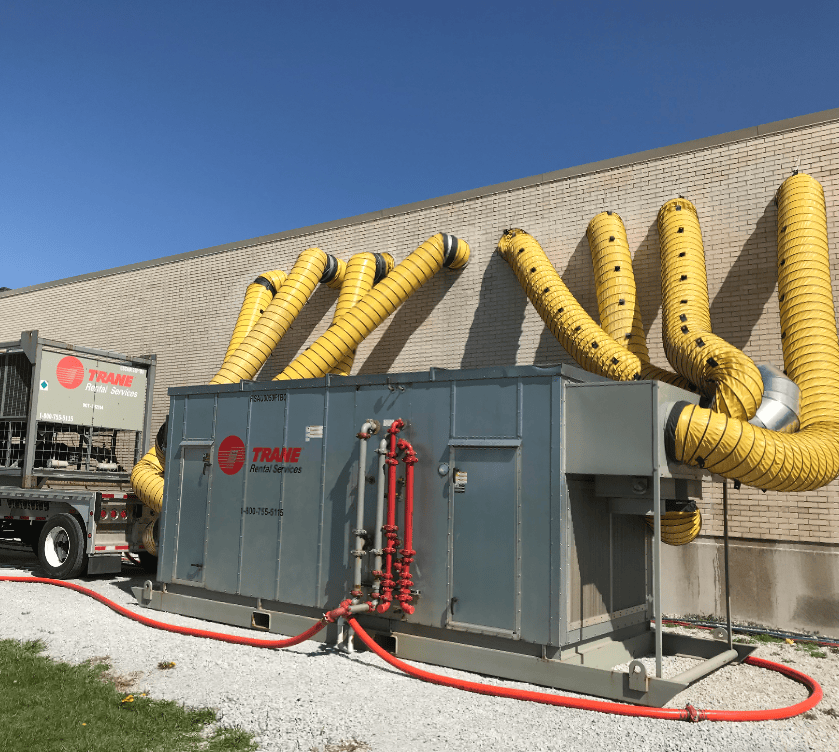

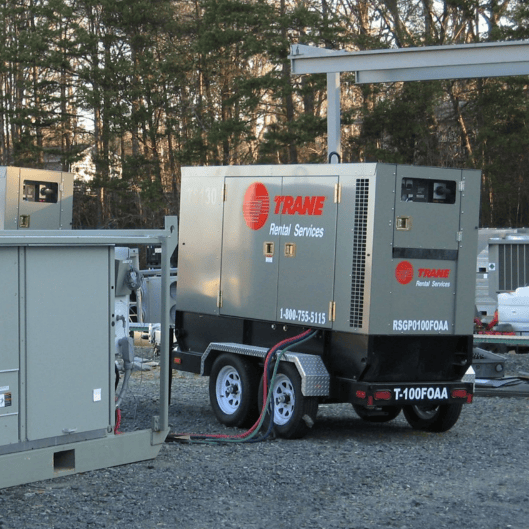

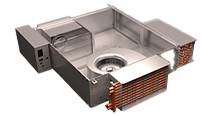

Rather than replace the aging chillers, the university collaborated with Haltom Engineering, CS3, and Trane to explore the CenTraVac R’newal® program. This factory—warranted overhaul service, offered by Trane, focuses on replacing high—use and heavy-wear components, and restoring chillers to like—new condition. By implementing this approach, the university was able to achieve several key benefits, including:

- Cost-Effective Life Extension: In lieu of replacing the chillers, the rebuild approach reduced the university’s investment by 80—85%, while providing new OEM factory warranties and an estimated 10 additional years water—cooled chiller life expectancy.

- Reduced Downtime: Replacing chillers would have resulted in nearly a year of downtime, severely impacting the university. By opting for refurbishment, and extending chiller life expectancy, each chiller was only offline for three weeks, and the process was staggered to ensure uninterrupted cooling throughout campus.

- Enhanced Building Automation: As part of the project, the university upgraded its controls and building automation system, enabling better system—wide energy optimization across campus.

- Expanded Cooling Capacity & Infrastructure Resilience: Upgrades to valves, filtration, and flow management addressed longstanding flow constraints, greatly improving indoor environmental comfort and stability. These enhancements not only support current campus demands but also laid the foundation for future system—wide optimization.

Results

“This approach enabled us to effectively recondition major equipment infrastructure that will serve the central cooling needs far into the future,” said Tony Poteet, Chief University Planning Officer, University of Memphis. “The State benefits greatly from this type of innovative approach, as it allows renewal and replacement funds to affect a greater range of deferred maintenance for the continued use of its assets.”

Beyond the chiller overhaul, The University of Memphis remains committed to continuous improvement. Plans include expanding building automation integration, optimizing chilled water plant status, remote pump operation, and air-side economization for greater energy efficiency. Additional safety features, including emergency response protocols for lab environments, are also in development.